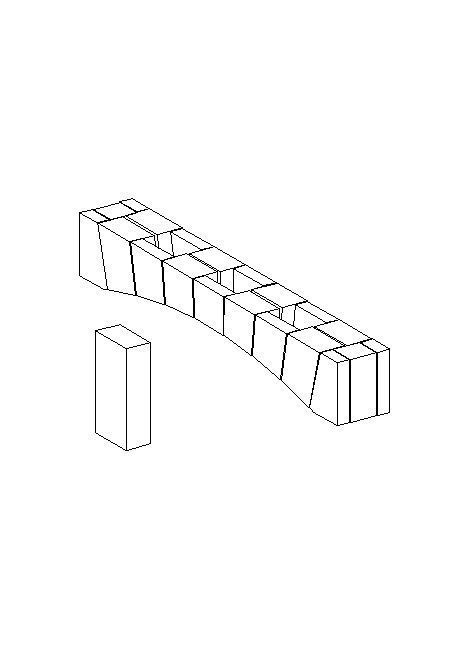

hearth form

I'm getting ready to pour my hearth, and am considering leaving the bottom of it in. If I used cement board in lieu of ply, i could just leave it in, correct? Should I use insulation board of some kind? I'm thinking about whacking a bunch of Galvanised screws through the bottom before I pour so it bonds better. I'll have photos as soon as we've capped the HEARTH STAND. Cheers, Nick

I'm getting ready to pour my hearth, and am considering leaving the bottom of it in. If I used cement board in lieu of ply, i could just leave it in, correct? Should I use insulation board of some kind? I'm thinking about whacking a bunch of Galvanised screws through the bottom before I pour so it bonds better. I'll have photos as soon as we've capped the HEARTH STAND. Cheers, Nick

Comment