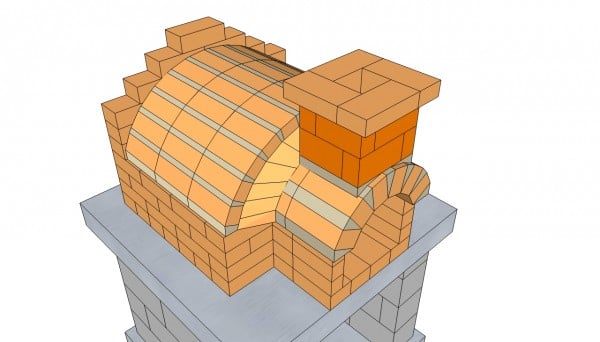

Hello from Utah. I just got my suspended slab poured and looking to start my rectangular dog house style oven. I wanted a little bigger oven so I was thinking 63"x 54", but I haven't seen anything quite that big. These are my questions:

1) Is there a a dome height ration that is too flat? I was thinking 10" - 14", but with a wider oven worry about the bricks falling?

2) I have a 5-1/2" reinforced concrete slab poured over metal deck. Do I need to put any fireclay mortar under or between the bricks on the floor of the oven?

3) What is the best, but cheapest mortar formula for the firebrick?

3) Is the chimney built into the top dome, or does it just sit on top and is attached only with mortar?

I was going to upload what I was basing my oven design on, but it said it was an invalid file? I appreciate any and all help.

Mike

1) Is there a a dome height ration that is too flat? I was thinking 10" - 14", but with a wider oven worry about the bricks falling?

2) I have a 5-1/2" reinforced concrete slab poured over metal deck. Do I need to put any fireclay mortar under or between the bricks on the floor of the oven?

3) What is the best, but cheapest mortar formula for the firebrick?

3) Is the chimney built into the top dome, or does it just sit on top and is attached only with mortar?

I was going to upload what I was basing my oven design on, but it said it was an invalid file? I appreciate any and all help.

Mike

Comment