Announcement

Collapse

No announcement yet.

Uk custom cast oven build - Tractors oven will this work?????

Collapse

X

-

Hi from Cornwall, Does anybody know where I can buy a mould for a pizza oven, something easy-ish pls lol

-

is there any reason why half of this thread has just disappeared? I had a lot of useful links I'd posted on page three which are now missing?

- Likes 1

Leave a comment:

-

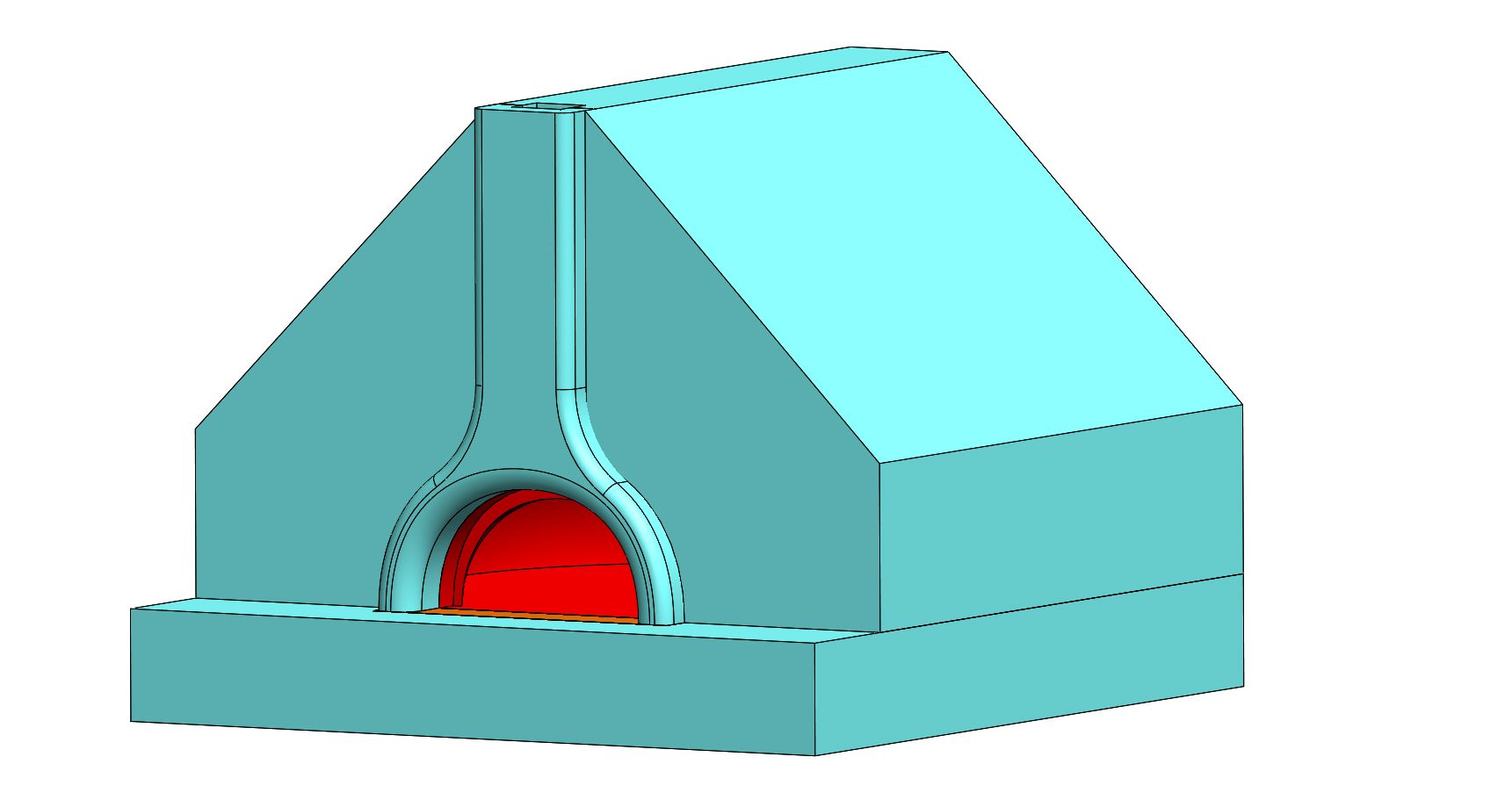

Remember that the flue gallery needs to be strong enough to support the flue as well as be resistant to abrasion from oven tools and feeding the fire. Use the attachment as a guide.Originally posted by david s View PostAs you are willing to use the Homebrew mix as your castable for the dome you may as well use it for your insulation mix. Replace half the fine aggregate with perlite or vermiculite. Ie 2:2:1:1:1 perlite, sand, lime, Portland cement, clay.

Attached FilesLast edited by david s; 11-10-2015, 03:28 AM.

Leave a comment:

-

I don't see why you need to separate the two sections. Unless you were planning on building a thermal break there, in which case you can cast over a couple of layers of corrugated cardboard there, remove it after the cast has dried and fill it with ceramic blanket, vermicrete or ceramic rope. It is easier, if you are casting in place, to cast the dome first, providing some form work for the door rebate. Once cured, for a min of one week for homebrew, remove the form work around the door and the mould under the dome, then build a sandcastle at the oven mouth, cover with wet newspaper and cast you flue gallery.

Using a mix of sand with 8-10% water by volume and a little powdered clay added, makes an excellent mould.

Leave a comment:

-

As you are willing to use the Homebrew mix as your castable for the dome you may as well use it for your insulation mix. Replace half the fine aggregate with perlite or vermiculite. Ie 2:2:1:1:1 perlite, sand, lime, Portland cement, clay.

Leave a comment:

-

Thanks for the info David much appreciated.

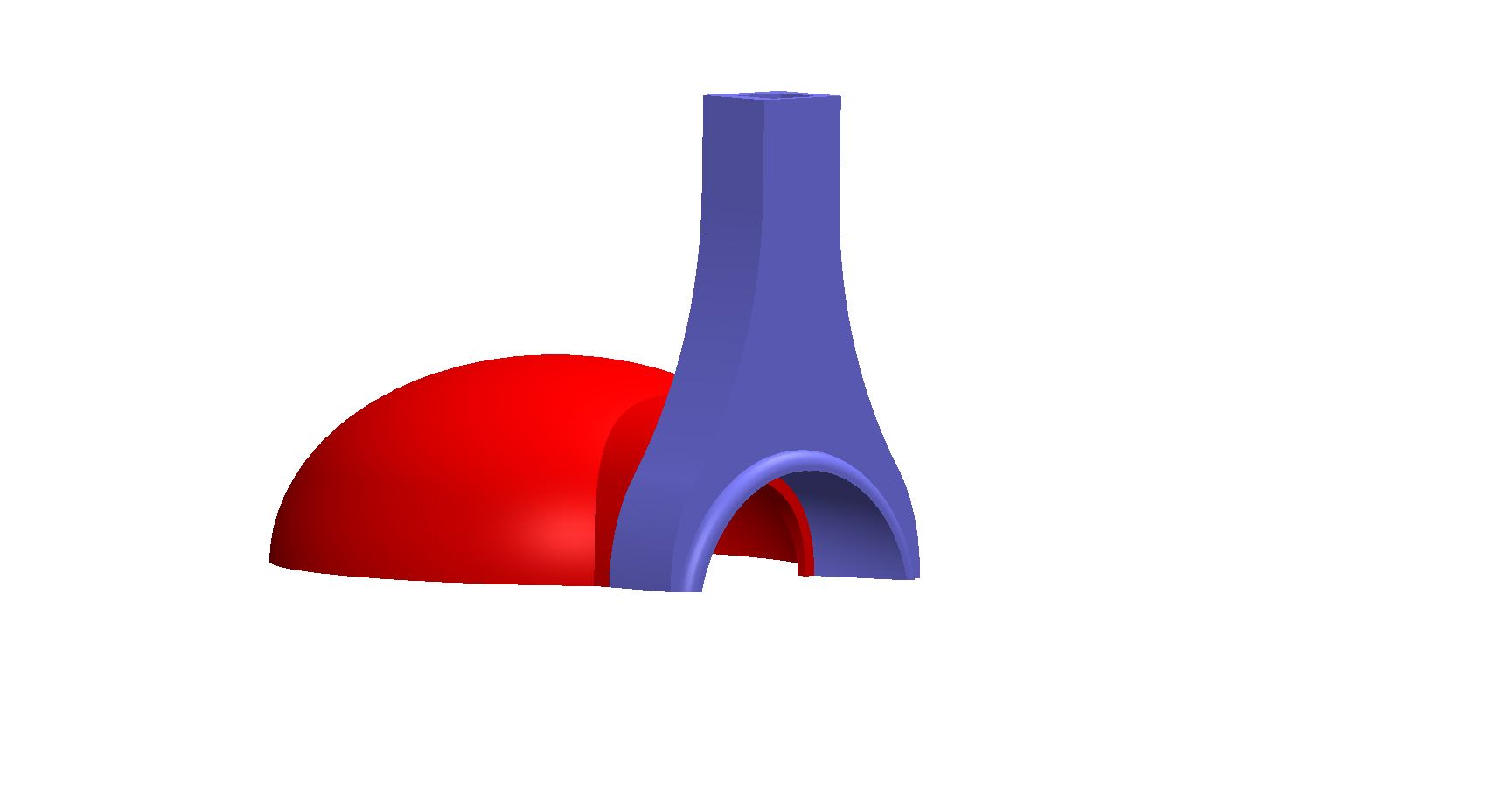

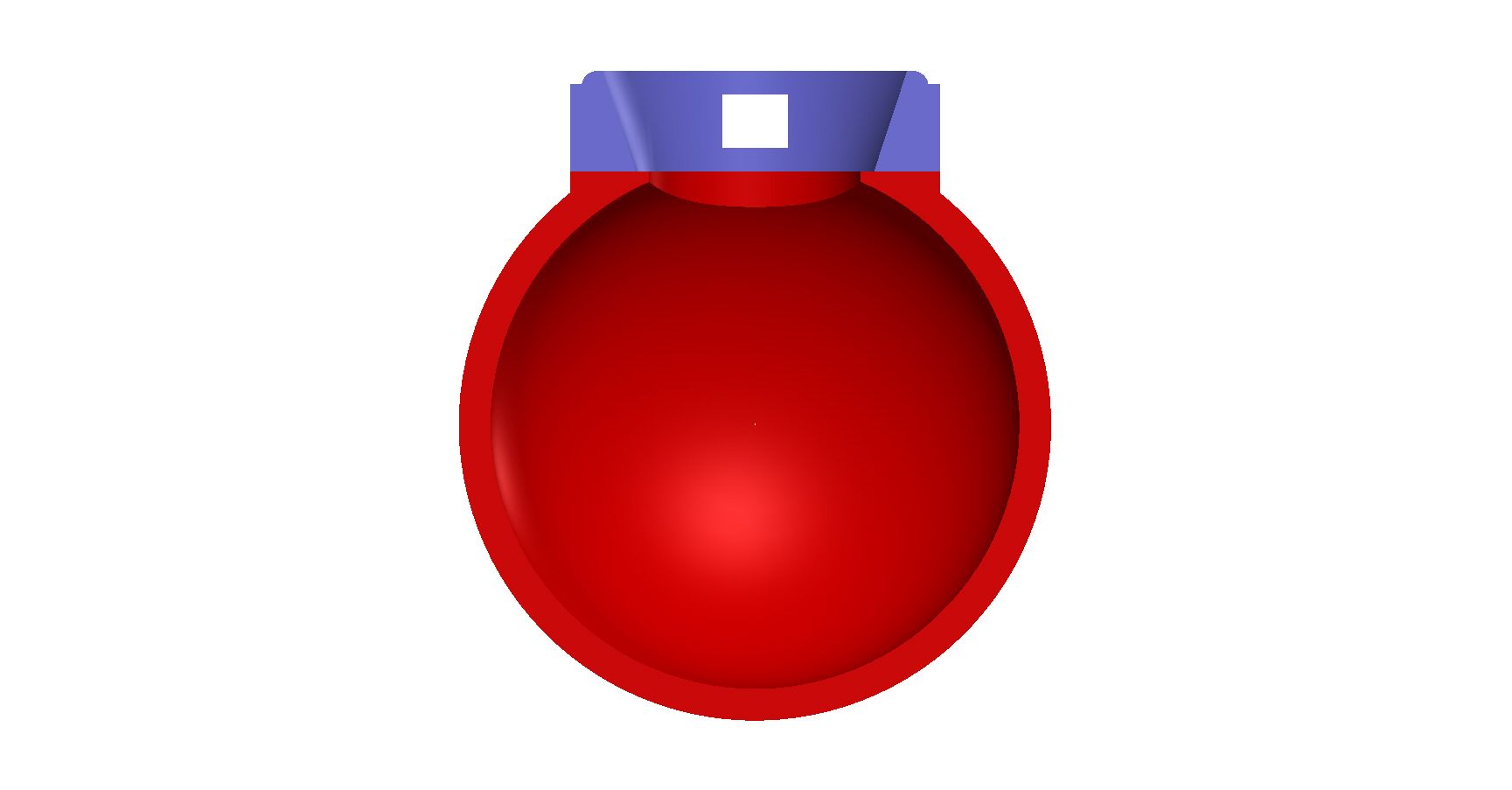

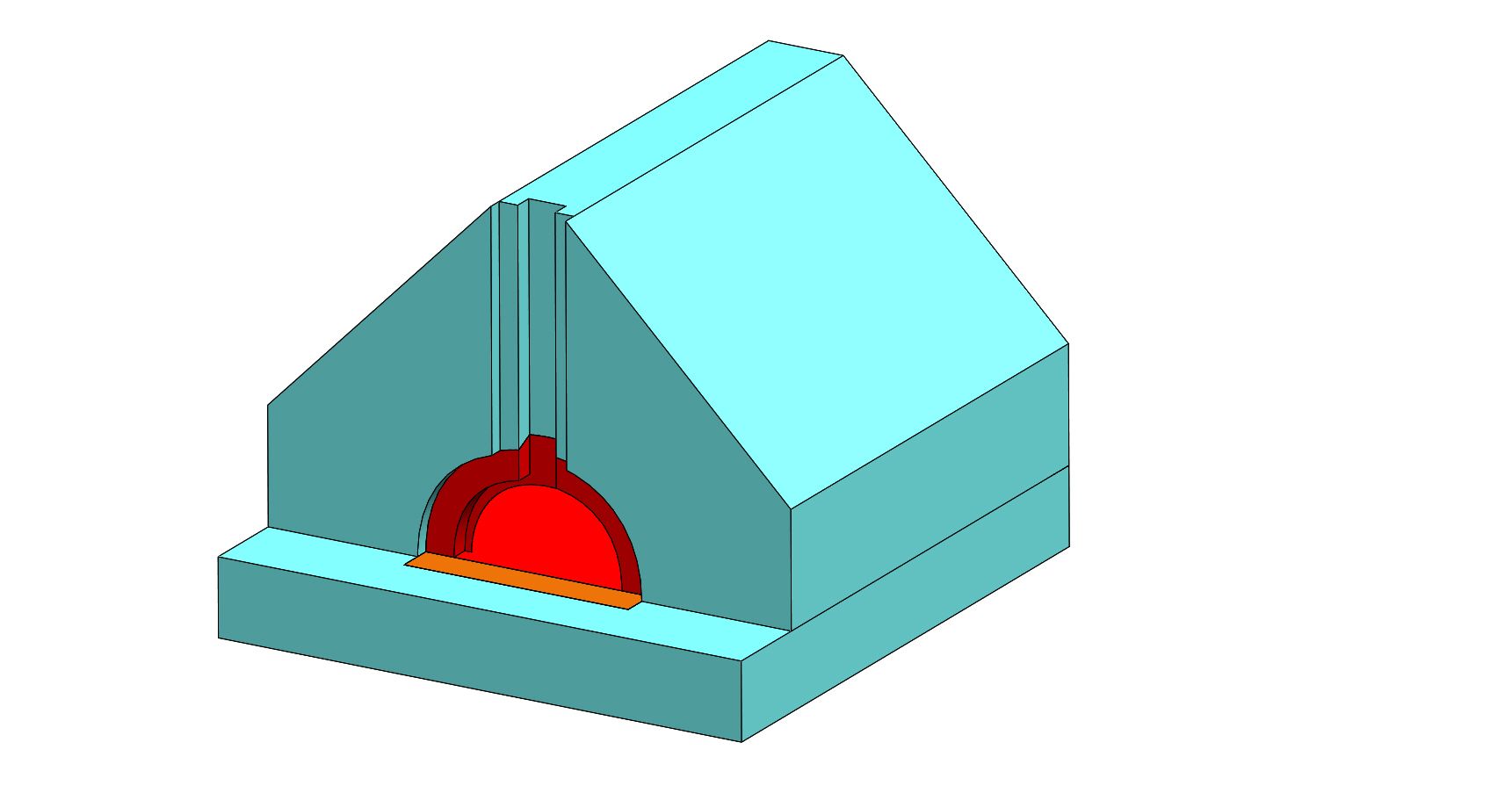

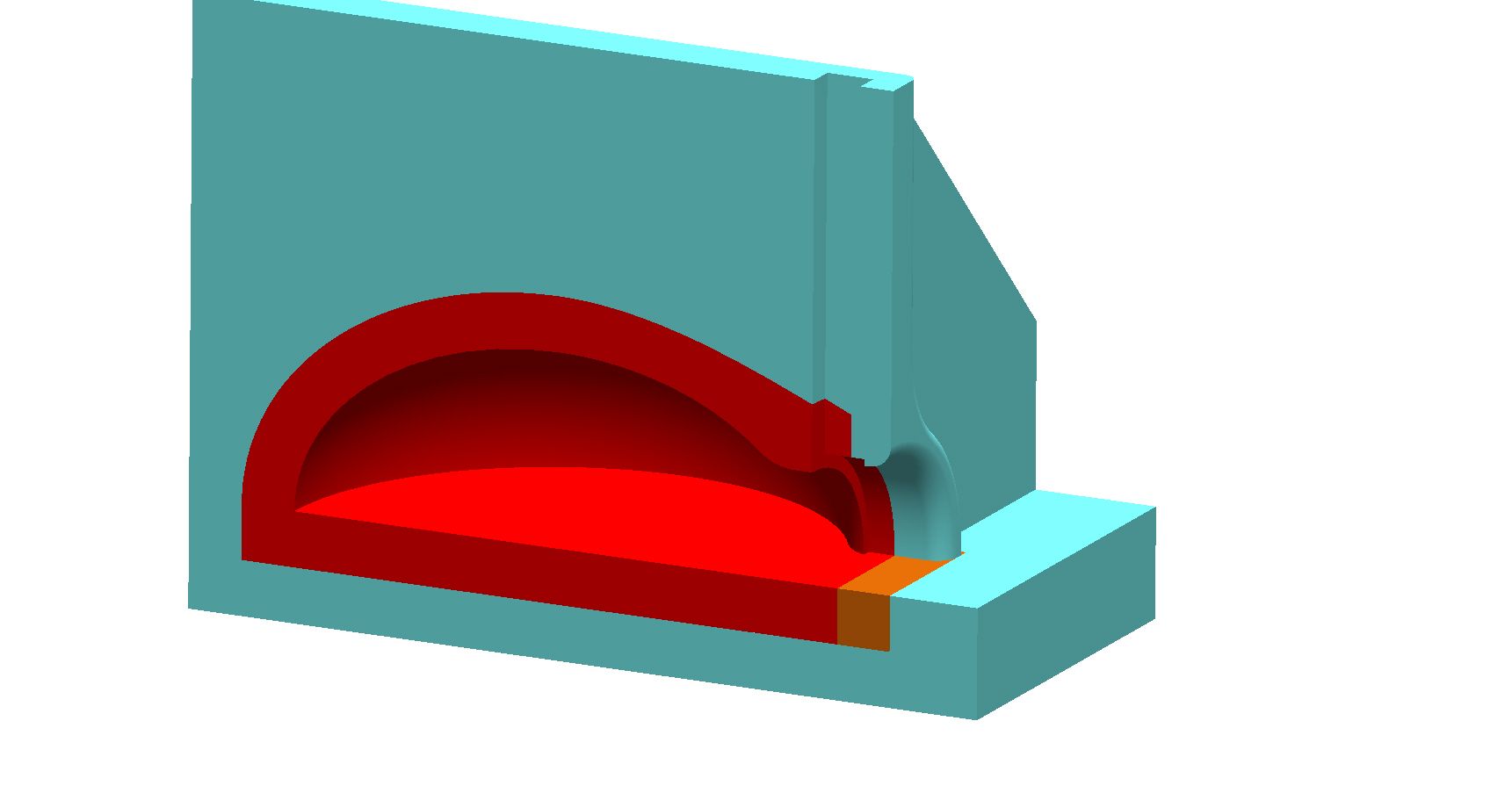

I've been playing around with a couple of new forms today and I thought I'd share this one with you. ( the more I do this the more I feel like I'm reinventing the wheel but I've got to try 😀

What I was thinking of doing was maybe casting the red sections using the 4-1-1-1 home brew mix and then maybe casting the chimney section in an insulation mix (not found a good one yet) but building on what David said earlier I might try and separate the two with a cut to shape sheet of vermiculite board and point it in with some fire cement ?

Here's the form I've been playing with today....

This is still based on 1000mm cooking floor and a 350mm high dome and this also gives me a throat depth of 160mm which with the angled entrance should give me plenty of access

Can anyone recommend any decent insulation mixes that will give me a good surface finish?

If not I guess I could cast the chimney in two sections splitting it vertically with the rear section being insulation mix and the front being traditional casting material. Roughly only a quarter of the chimney will be visible anyway

Cheers

TracLast edited by Tractor; 11-09-2015, 01:45 PM.

Leave a comment:

-

Good plan. Use a min of 2% by weight of the dry castable mix for the stainless needle addition and make sure you get the correct plastic fibres. You need polypropylene fibres, don't try cutting up some polypropylene rope. I've done some tests on them and found they do not melt at a low enough temp. You need the short super fine stuff that is one of many types used for concrete reinforcing. You can get them from concrete technology suppliers. Around half a handful for a batch of 20 L of castable is sufficient, but you need to mix about double the normal time to get good dispersal through the mix.Originally posted by Tractor View PostI was thinking of adding plastic needles as well as stainless ones, so the plastic ones burn off and leave voids and the stainless ones stay and help strengthen the whole structure

Trac

Leave a comment:

-

I was thinking of adding plastic needles as well as stainless ones, so the plastic ones burn off and leave voids and the stainless ones stay and help strengthen the whole structure

Trac

- Likes 1

Leave a comment:

-

4" is very thick for a floor. Generally the floor thickness and dome wall thickness are the same. It depends on how much thermal mass you want your oven to have and the strength of the walls and floor required. Most commercial cast ovens are around 2" thick. Personally I wouldn't be relying on the home brew for a cast floor. While it may be ok for the dome I doubt it would stand the test of time for a floor, but by all means go ahead and prove me wrong, I'd be most interested.Are you planning on using any reinforcing?

Leave a comment:

-

Hi David yes your right. The floor will most likely crack if I leave it as above so what I plan to do is to cast it in five pieces, if you imagine quartering the floor but also having a circular disc in the centre you won't be far off

I was planning on casting it 100mm/4 inches thick but I'm starting to think that's too thick really, firstly because of cracking due to uneven temperatures but also the thicker it is the longer its gunna take to heat up.

Perhaps I'll go for 60mm as a compromise between thermic mass and speed as this won't be an industrial oven I'll have plenty of time to rake the hot embers back over the cooking surface if needed.

Thanks for your suggestion around the entry material I'll look into it.

Also a note to myself here's a good project that uses homemade refractory cement, http://www.fornobravo.com/community/...cost-wfo-build

I'll probably go for the 1-1-1-4 recipe being 1 Portland cement - 1 lime - 1 fire clay and 4 sand purely because these materials are a lot easier for me to source.

Has anyone here had any experience using this recipie? How are you ovens holding up?

TracLast edited by Tractor; 11-07-2015, 04:16 PM.

Leave a comment:

-

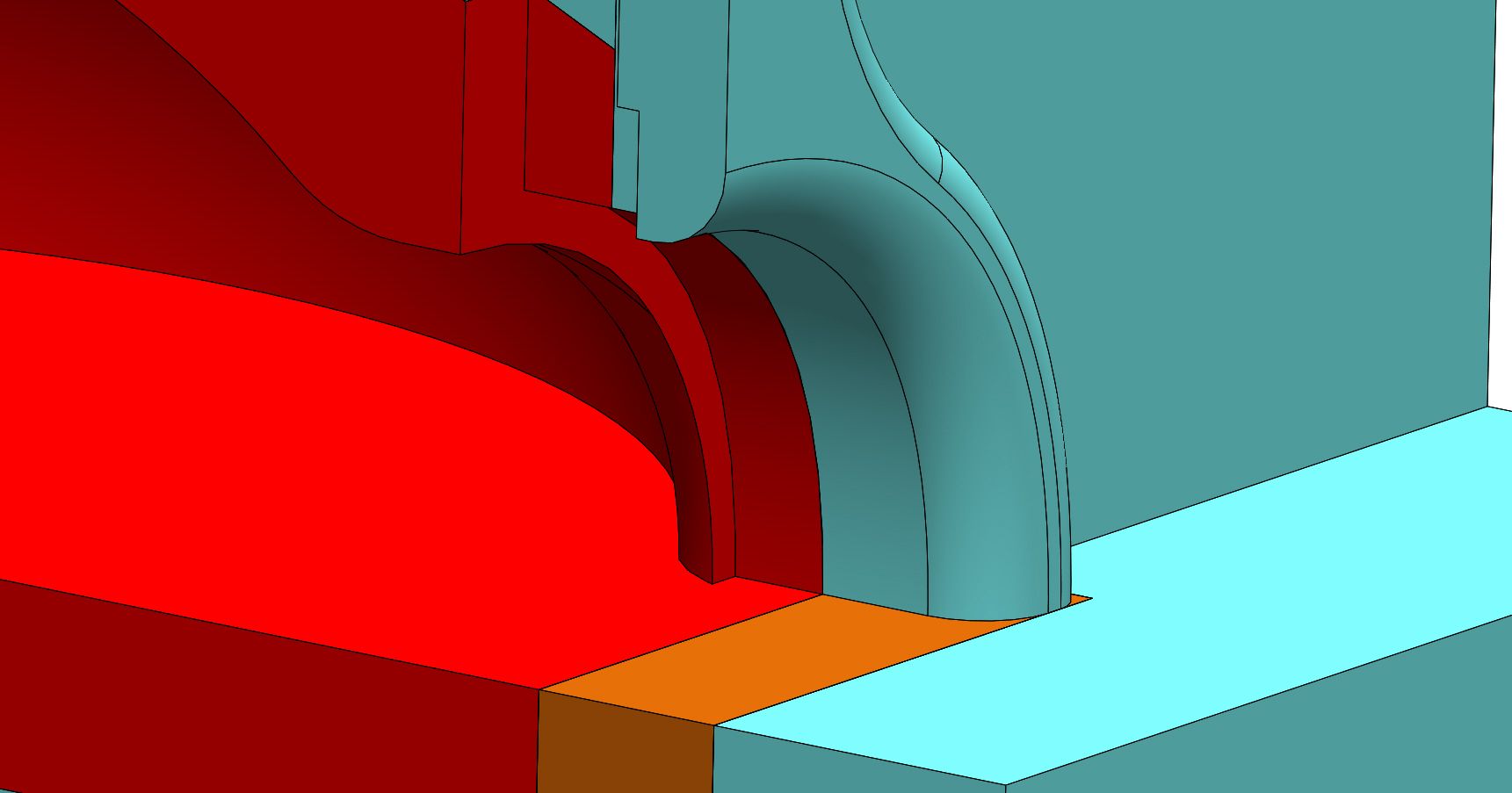

"Q - the bit I've coloured orange bridges underneath the door and if cast as part of the oven floor will it conduct heat out of the oven when the door is in place? and if so do you guys recon i'll be able to cast that section as part of the insulation slab? I don't want to move the door further out because that will mean its the wrong side of the chimney"

Firstly, if you cast the oven floor in one piece it will crack. Any large cast sections are vulnerable to this problem and none more so than the floor. It is for this reason that most WFO floors are smaller units (firebricks) and have no mortared joints.

Secondly, if you cast the floor section under the entry using an insulating mix it will not be particularly strong and will be subject to abrasion from moving pots and tools over it continually. There are a couple of solutions I can think of and that is

1 to cover over the area with thin stainless which is durable. Or,

2 use a dense refractory material like firebrick there, but separate it from the oven floor with a thermal break of around 10mm This gap can be filled with blanket and the top cm or so topped with vermicrete to seal in the blanket.

Don't change the position of the door.Last edited by david s; 11-06-2015, 09:41 PM.

Leave a comment:

-

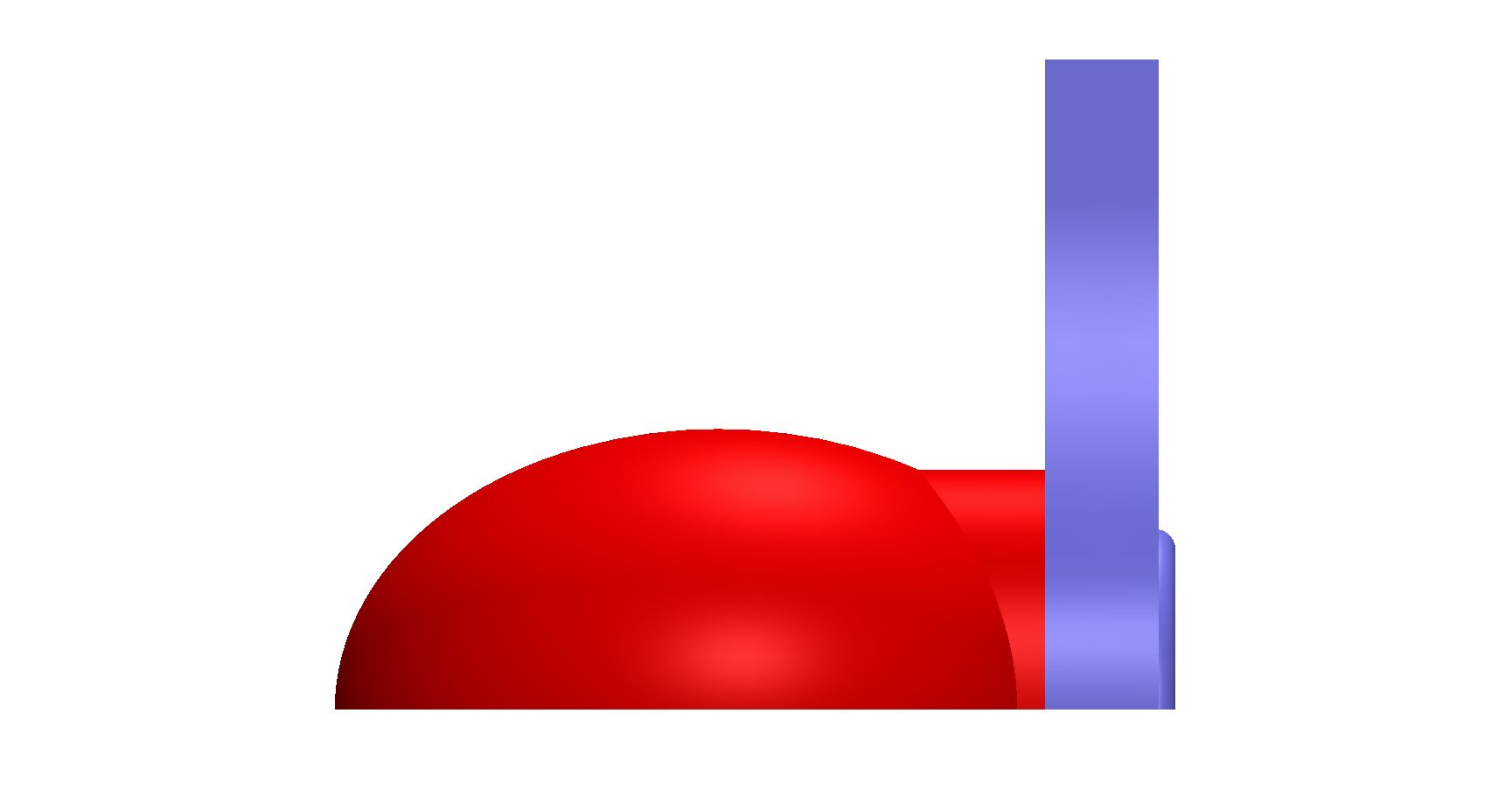

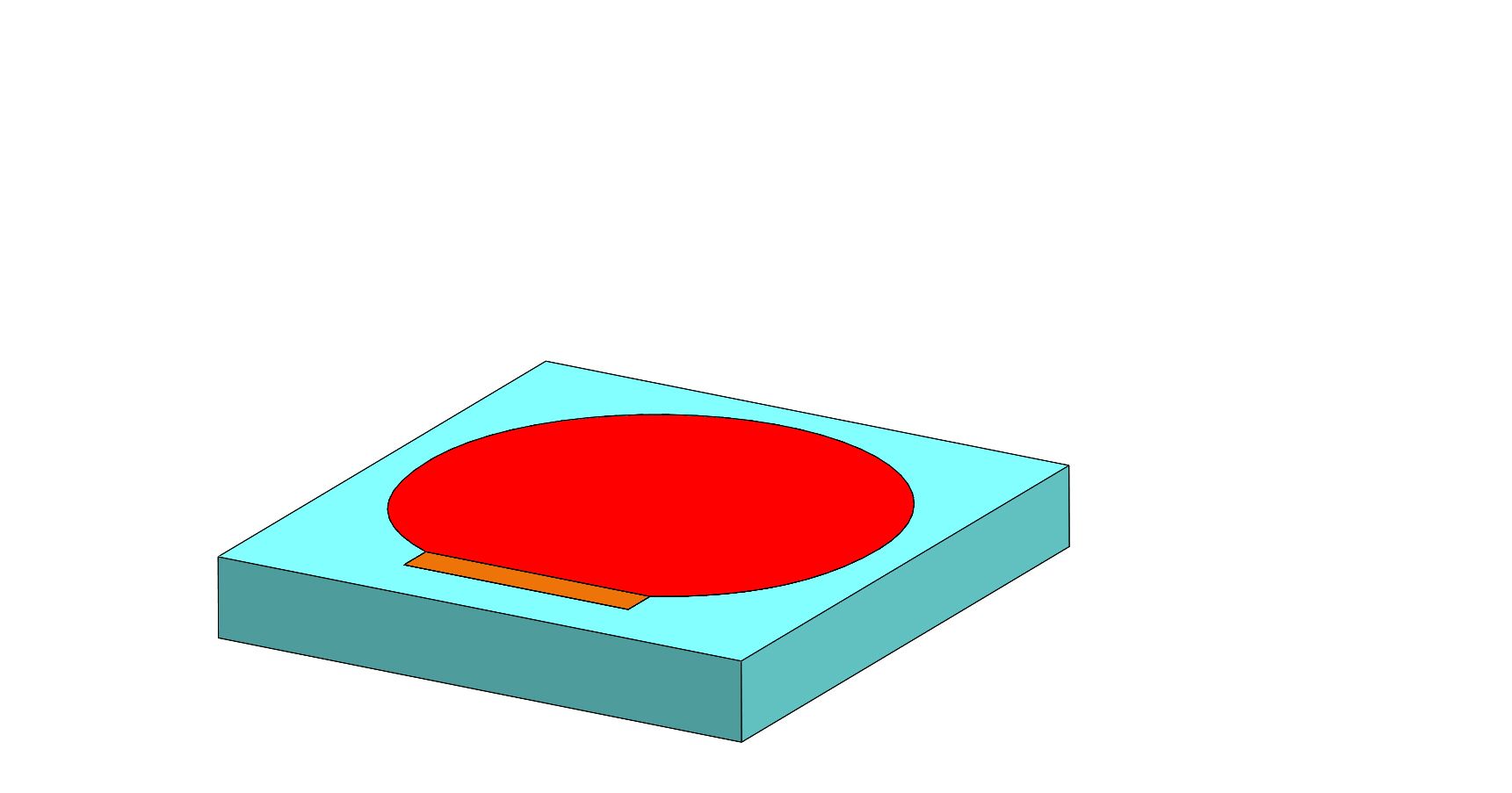

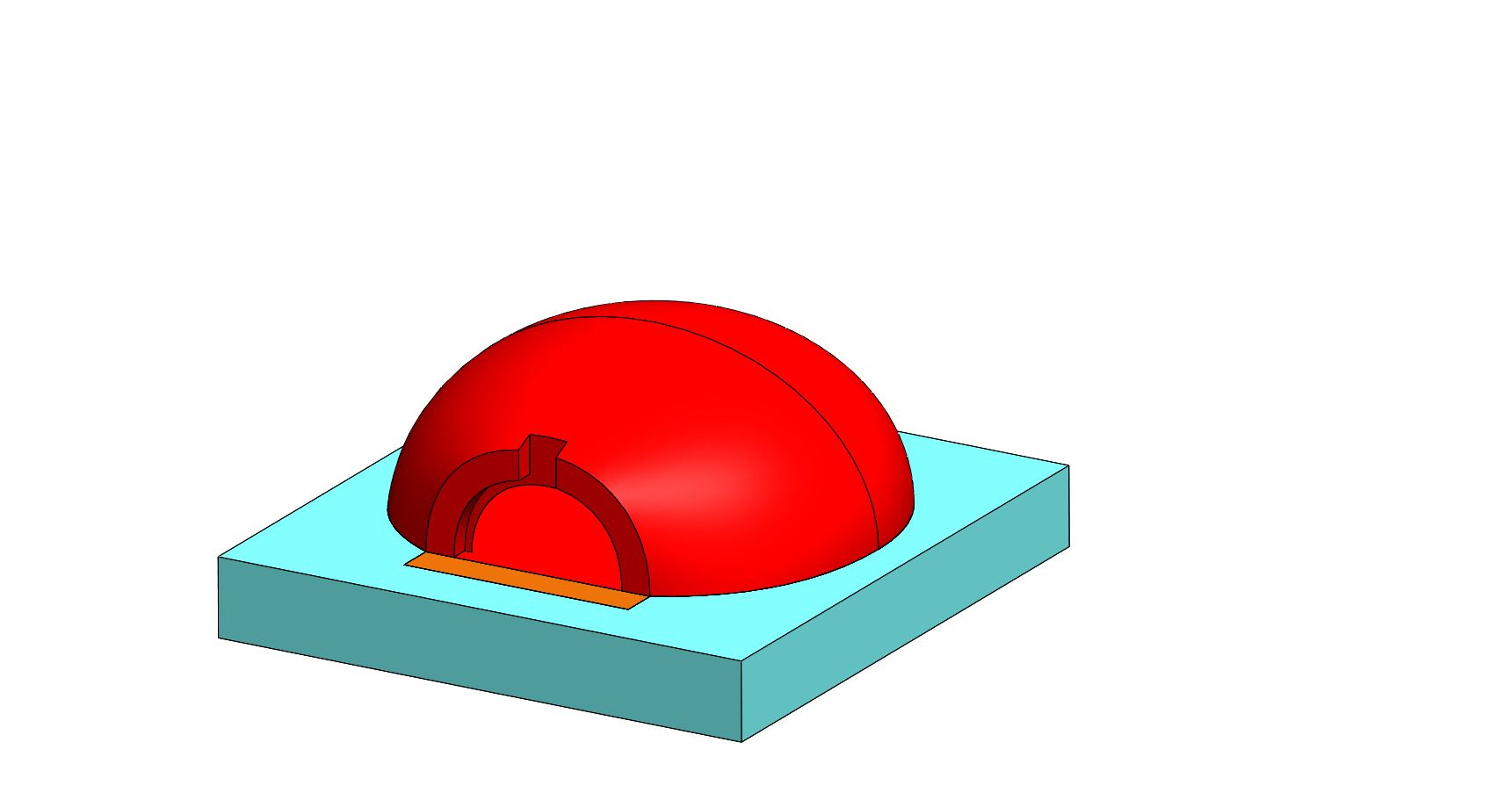

hey guys thanks for your advice its much appreciated sable I don't know whats going on with the photos it was a right pain to get them to show I'll have to go back and re read the how to upload photos sticky. I measured my pans and a 400mm opening should be fine. David I revisited the initial shape of the internal and your absolutely right the roof of the oven is far to flat, that's something I missed and out of interest I did just raise it 100mm and it gives a much better shape, I've kept the floor at 1000mm and played with the roof surface to make it as smooth as poss. I have only raised the opening up to 200mm. the oven is 350mm tall in the centre so applying the 63% rule gives an opening height of 220.5mm which I modelled up but it just looked way out of proportion so I've gone with 200mm. I'll do some flow analysis at somepoint to test to make sure the fire will still draw ok I do plan on having a door to retain residual heat so I've modelled in the flange for it to sit up against. heres the revised oven........... a couple of things I should explain..... everything coloured in red I plan to cast in a refractory cement and everything in blue I plan on casting in an insulated cement to help retain heat. Q - the bit I've coloured orange bridges underneath the door and if cast as part of the oven floor will it conduct heat out of the oven when the door is in place? and if so do you guys recon i'll be able to cast that section as part of the insulation slab? I don't want to move the door further out because that will mean its the wrong side of the chimney cheers guys good to catch up trac

1 PhotoLast edited by Tractor; 11-09-2015, 01:36 PM.

1 PhotoLast edited by Tractor; 11-09-2015, 01:36 PM.

Leave a comment:

-

I'm sure this design would work, but not so sure you'll get good circulation with the form of the oven being so flat. Even a slight curve on the roof would increase the strength of the dome enormously rather than having a flat one. Your new proposed oven mouth dimensions are almost exactly the same as mine, yet my oven is only 540 mm in diameter and its form is hemispherical. I can just squeeze in a 5kg turkey through my door. I feel you would be better to raise the height of the dome 100mm and also the height of the door in proportion. Also the floor in the entry, especially right up near the oven opening is probably too hot for standard concrete to cope with the heat there, suggest you use fire brick for at least another 100 mm there.Last edited by david s; 11-05-2015, 01:04 PM.

Leave a comment:

Leave a comment: