This is an independent Forum, you can email us at support@fornobravo.com and we will send you the correct board.

Reference this thread and one of our sales representatives can get in contact and make it right.

Sorry for the mix up.

Our marketing manager monitors the forum and should have caught your post.

Tim

Forno Bravo

COO

Announcement

Collapse

No announcement yet.

JayMez and the Oven Design

Collapse

X

-

I am not sure where you are located but check with EJ Bartells (AKA Distribution International). They carry CaSi board called ThermoGold 12. Also try Harbison Walker. Both of this companies have distribution stores through out the US

Leave a comment:

-

I did not mention the patio.I designed it, I like the patio. They also poured the counter and the hearth, the counter has some unwanted pockets at the bottom. I sort of give that the benefit of the doubt as it has held up and hasnt shown a sign of being a problem in the least, I kind of want to fill it in with something called entropy resin that I bought and keep the cool look. I will polish the top of the counter or I could just leave it as is because it looks and feels fine. In the 3rd pic down you can see what I'm mentioning.

Leave a comment:

-

Hello,

It's been such a long time. I feel embarrassed to say I let my project go for a long time ( again). Now I'm back to finish it. Below should be some pictures of the progress I had made more recently than the six years since I started this. My oven design has a corbel design that creates a bucket to suit the desired height of my hearth. In that bucket or depression goes the ceramic insulation board which I am now having trouble getting. On that goes my hearth, Dome, flu, FB blanket, and perhaps a certain amount of vermiculite or perlite. The usual suspects. I will then house it all inside 4" masonry and facebrick with a concrete cast roof. I have access to expandable polystyrene/ styrofoam for casting the roof. The family business is EPS products for packaging, mainly coolers but also custom fabrications and I am pretty confident I can pull off the design I've made. If not it will change.

I'd like to mention a problem I'm having. I had ordered some FB board for under the hearth and it said 3 boards on the outside so I never opened it up. now that I have time to work on it Forno Bravo must have put in an order for their FB board and a mistake was made because instead of 3 boards at 2 inches thick I got 2 boards at 3 inches thick. I have tried sending a message on here but it was never responded to. I realize it's over a year old but I have a feeling either they didn't get it or it was ignored. It would have been okay by me if they told me they couldn't refund it or give me anything for it. At least I tried. So I found a place that sells ceramic board located much more locally called Zircar Ceramics, but they want at least twice as much maybe even 5 times as much for admittedly what seems like a superior product for use in the same firebrick backing projects.

I was given a price of 528.00 for a pack of 3 which is about what I would need, but I also asked for them to include shipping in the price. Forno Bravo would probably be up around 300.00 for 3 boards and shipping. I was hoping I could make a deal on the boards I already bought. The frustrating thing is I've bought the FB board twice now. The first time the rain got to them and they had gotten dirty and clumpy and were rendered unusable, which was totally my fault and bad luck. I'm a victim a circumstance!

Anyway if anyone see's this and can help I'd appreciate it. Here are some pictures of my progress.

The scaffolding or whatever you'll call it, is for a tarp cover that has since leaked in spite of a grade and because one forgets that polyethylene tarp just loves to get holes in it. I should have put some plywood sheets up under it though it might not have happened. going to fix that.

1 Photo

Leave a comment:

-

Re: JayMez and the Oven Design

I looked into This Metal Dome design and the ratios of basalt are posted in Wiley's page and ... I like it, However I will be building a Pompeii Oven out of firebrick using a good old taper and design implementations discussed previously on this forum.

1. even though the metal dome prevents the refractory from coming down onto the pizza if and when it cracks up ...I still think that brick are probably an easier maintinence issue and can be replaced much easier and will , in theory, "be used" for a longer period of time(that appeals to me).

2. I have also had a very fun idea of my own that utilizes the idea of maintaining an oven for further use. It has to do with the exterior design... but as in any design there are pros and cons that I will work out as much as possible before bringing it here for serious consideration for implementation.

But here are some pictures as promised I do like to upload them myself instead of hosting them here (hope no one minds)

Last year

This Year

Leave a comment:

-

Re: JayMez and the Oven Design

Dave, I did just that, but I didn't learn anything new. Wiley wrote about an aggregate if I'm not mistaken . Some taprock or basalt. I'll be looking into those posts that seem to be the origin . Pics imminent.Originally posted by david s View PostJaymez,

If you're after Fondue try a search on the forum for "Ciment Fondue" , "Castable refractory", or "calcium aluminate"

Dave

Leave a comment:

-

Re: JayMez and the Oven Design

Jaymez,

If you're after Fondue try a search on the forum for "Ciment Fondue" , "Castable refractory", or "calcium aluminate"

Dave

Leave a comment:

-

Re: JayMez and the Oven Design

I don't know anything about pooring, but if you are going to cut bricks I would tell you to get a saw. Any saw, that is to make nice clean cuts. Breaking them sounds like a nightmare when you want to make a specific size brick. Most people use the somewhat disposable Chicago brick saw from HF.

Mike

Leave a comment:

-

Re: JayMez and the Oven Design

An update-

.I will be posting some pictures of progress soon. As for the brick layout of the dome I'm thinking about making a dome like Wiley's steel dome. http://www.fornobravo.com/forum/f43/...oven-3717.html It's a better design IMO. I feel as though I have similar recources and ability. However, I "don't remember" seeing Fondu Lafarge on here or any mention of mixing it with basalt or taprock when I was looking into casting (can anyone provide me with a link or fill me in on how it's used?)

So now that the rain is subsidingwhere I am I recently poored the floor of my foundation (not the hearth/oven floor to avoid confusion) and I got my head back into the firebrick layout of my oven. In consideration of shortening brick I just did a little google sketchup designing and some math and to make a long explanation short it seems that generally tapering your brick is more cost effective and more efficient.

My Fathers Father used to own a galvinizing business (he also used to collect junk) but he apparently had to cast something in refractory to use as a smelter ...and so after telling my dad about the design of the brick he says "ya know ther's another way you can do that." I went on to tell him about how cracking is a real problem with these builds but he insisted "not if you do it right" and so I'm now inclined on maybe looking around for a steel container to go with a Wiley design (my dad may even have an old one) or looking for something castable.

If there are any among you who think that I shouldn't take this route speak now ... if not speak later and I will probably only be up to pooring my oven floor anyway.

Leave a comment:

-

Re: JayMez and the Oven Design

When designing your entry way, consider that when cooking, you have to reach in and see in. You may want to consider making it as shallow as possible - just deep enough to support whatever vent / chimney you decide on.

I may be missing something, but if you want to use thinner bricks have you considered "splits" which are 1 1/4 x 4 1/2 x 9 ?Last edited by Neil2; 06-25-2010, 11:17 AM.

Leave a comment:

-

Re: JayMez and the Oven Design

I talked to the makers of Heat stop 50 today. They indicated teh density of heat stop 50 mortar is about 75% of firebrick, but they had no data on the specific heat or conductivity of the mortar.

He agreed with my guess that heating times for mortar and brick would be similar (but I think he was just guessing).

He asserted, as did Dino, that the mortar is intended to be used for narrow joints to hold the fire brick together.

Leave a comment:

-

Re: JayMez and the Oven Design

I'm not certain the thermal mass of this 42" dome made with 1" thick brick would be any higher then a dome made with 2 1/2" thick brick. The dome is still 42" at the base and I presume hemispherical.

A dome with thicker brick might have more refractory mortar but the question is which holds more heat (technically which has a higher specific heat). It's actually possible the mortar has a higher specific heat and that this oven would heat faster. A quick google search and I can find a value for the specific heat of fire brick, but nothing for refractory mortar (and I'm sure both fire brick and refractory mortars vary a lot).

Has anyone done any measurements to try to figure out which takes more energy to heat up? (E.G. make a chunk of refractory mortar with the same weight as a chunk of fire brick and heat both with a torch for 5 minutes and measure how much the temperature changed? You would want a small mass of both so you don't get confused by the conductive properties.)

Leave a comment:

-

Re: JayMez and the Oven Design

The Brick texture in sketchup is just to show how that is the floor brick and not a piece of FB board or something. I plan to do a herringbone pattern. I did not recieve a response via email. However today I drove over there as the place is right by where I work. I didnt get a full spec on anything other than the fact that a split fire brick would cost me $1.43/brick . I am now the happy owner of a free sample of one . I am thinking I will cut the split brick as it is 1 1/4" and the dimension originally planned is 1"x2.5x4.5". The Dimension now would be 1 1/4"x 2 1/2"x 4 3/8" . I am going to see if its viable to split this block along 3 lines in the block to get 3 regular blocks and one 1 and 1/4" x1 1/4" block for the top of the dome.

. I am thinking I will cut the split brick as it is 1 1/4" and the dimension originally planned is 1"x2.5x4.5". The Dimension now would be 1 1/4"x 2 1/2"x 4 3/8" . I am going to see if its viable to split this block along 3 lines in the block to get 3 regular blocks and one 1 and 1/4" x1 1/4" block for the top of the dome.

Dino I appreciate your input and I'd like to know is the refmix still available? I don't see it in the FB store. I am generally not informed on where I might get some. Either way I need a choice of mortar.

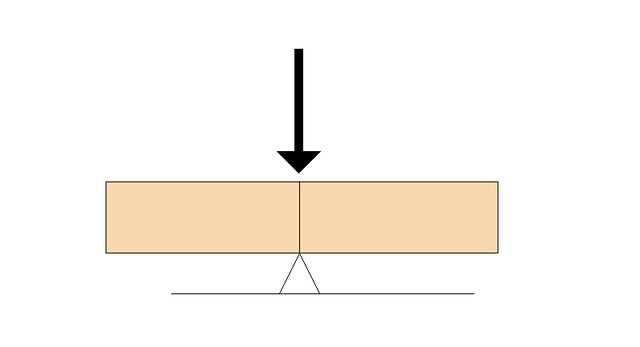

My father was telling me that him and his father had built a furnace once and that the way they split the brick was to weld a piece of metel sticking up off a platform like seen above. So I am going to be experimenting a little with my free brick. In the mean time make of this what you will.

Thanks so far for your input

Leave a comment:

-

Re: JayMez and the Oven Design

I agree, herringbone is easy to do, looks interesting and I can attest to the odd edge that sticks up here and there and my peel and pans slide right over.

Also, I was just about to discourage you from cutting a brick into so many little pieces. That's a lot more cuts, a lot more $25-$100 diamond blades and bricks dust/clay caught in the wet-saw's water pan is a pain to wash out every day. It's also harder to offset the vertical joints to avoid longer cracks.

HOWEVER, that said, for a 42" oven using half bricks, we (most) end up going to 3rds anyway by the 4th course and soon after near the top, 4ths, 5ths and more to close the thing up. So cutting whole fire brick into smaller pieces early on is only a little more work. But still, although I certainly can appreciate the look of tiny brick pieces (it would be so cool ) After you finish it, you don't see it that much in your oven. IMO just using 3rds for the whole thing (ok 4ths) would get you there too without much more work.

) After you finish it, you don't see it that much in your oven. IMO just using 3rds for the whole thing (ok 4ths) would get you there too without much more work.

Also, I really like how you plan on going without a tall soldier. You are correct, it is a week spot (though certainly not a real issue).

Also remember: You want your oven to be made of firebrick with as little of mortar as needed to hold it (ideally). Smaller bricks will help you get a tighter fit if done well but so will good taper cuts (hopefully better than mine ). I used FB's Refmix for 70% of my oven and I love it...really strong stuff.

). I used FB's Refmix for 70% of my oven and I love it...really strong stuff.

Great job on your sketchup and it's admirable you are planing this out so well. It will be a better build for all thought and work.

-Dino

Leave a comment:

Leave a comment: