Re: Apagios's 42" Pompeii

Thanks - food for thought apagios. Much as I don't want to I feel you are right about those bricks. Even my wife who is my worst critic doesn't want them hidden.

Thanks - food for thought apagios. Much as I don't want to I feel you are right about those bricks. Even my wife who is my worst critic doesn't want them hidden.

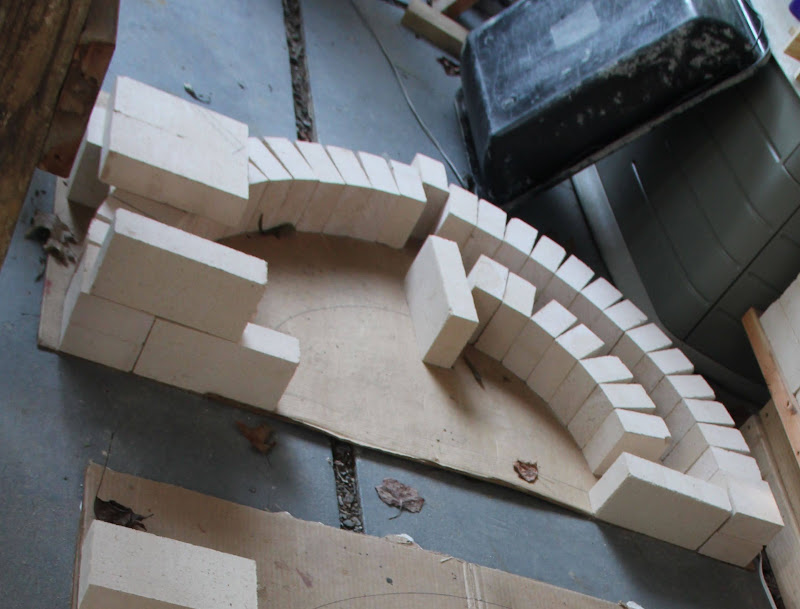

On second thoughts maybe I'll follow your advice - get some normal bricks and do it the sensible way unless someething like this could be done with the firebricks?

On second thoughts maybe I'll follow your advice - get some normal bricks and do it the sensible way unless someething like this could be done with the firebricks?

Comment