I've spent ages getting round to building a door for my oven, and I wanted to build it out of materials I had to hand. Unfortunately, I botched it. Twice. I thought I'd post the details, since it might help someone else. I can't be a good example on this - so instead I'm being a warning to others...

My first step of building a door was to fix together some 1" thick bits of oak (old floor boards) to make a door. I framed it with aluminium channel to protect it from the heat. This didn't work (more on this in a bit...). The handle was made from an oak branch, planed on one side. I coated the lot with sodium silicate, which dried to a nice shine and looked pretty. This also turned out subsequently to be a stupid idea - I'd forgotten sodium silicate was intumescent (i.e. would swell up like popcorn in the heat) ...

I was pleased with this, and moved on to insulating the back of the door. I spent a long time moulding a nice plug for the door entry out of my insulating mix (vermiculite, fireclay, cement and sodium silicate), attaching it to the back of the oak with metal ties. The insulating mix dried, cracked a bit, dried some more, cracked a lot more, then fell apart when I lifted the door up.

Lesson 1: my insulating mix is good for filling cracks, and coating chimney insides. It's not good for making doors. It works in small thin sections, but big bits crack. A lot.

Door number 2 was made by using the wooden front from door number 1, then carving two thermalite blocks to act as a plug for the oven. They were fixed to the oak door using screws - the carving was very easy thanks to the softness of the AAC blocks. This looked promising.

Pleased with this, I had a nice big fire and stuck the door in place after the coals had cooled off for 10 minutes. By watching the temperature I could see that this door worked well. I'll add the graph below - notice that this graph's over 28h, and the dome surface takes 6 hours to cool from 300C to 200C - twice as long as it did without the door. I thought I'd cracked it, but unfortunately:

- the sodium silicate round the edges of the door had erupted into a white fuzzy mass in the heat, and looked horrible

- the wood around the door had charred badly, causing the aluminium frame to come loose, and in one place, fall off

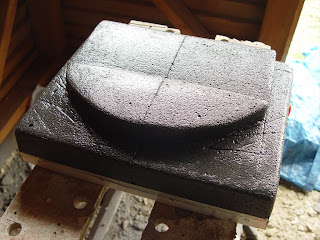

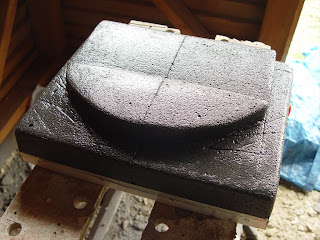

- the wood on the back of the door had warped with the heat and cracked, causing the thermalite block to move and crack as the wood bent. You can see one of the big cracks in the block below. The bit at the bottom is a loose chunk that fell off when I lifted the door.

The thermalite block was still solid, if a bit more brittle than before, but the wood was badly burned around the edges. This wasn't a great example of how to build a door - perhaps more of a warning to others!

Lesson 2: Don't use wood for the door - I'd underestimated just how hot it would get round the edges. This is probably my own stupid fault for putting it on when the oven was so hot...

Now I need to make door number 3 - an all metal version, probably filled with vermiculite...

My first step of building a door was to fix together some 1" thick bits of oak (old floor boards) to make a door. I framed it with aluminium channel to protect it from the heat. This didn't work (more on this in a bit...). The handle was made from an oak branch, planed on one side. I coated the lot with sodium silicate, which dried to a nice shine and looked pretty. This also turned out subsequently to be a stupid idea - I'd forgotten sodium silicate was intumescent (i.e. would swell up like popcorn in the heat) ...

I was pleased with this, and moved on to insulating the back of the door. I spent a long time moulding a nice plug for the door entry out of my insulating mix (vermiculite, fireclay, cement and sodium silicate), attaching it to the back of the oak with metal ties. The insulating mix dried, cracked a bit, dried some more, cracked a lot more, then fell apart when I lifted the door up.

Lesson 1: my insulating mix is good for filling cracks, and coating chimney insides. It's not good for making doors. It works in small thin sections, but big bits crack. A lot.

Door number 2 was made by using the wooden front from door number 1, then carving two thermalite blocks to act as a plug for the oven. They were fixed to the oak door using screws - the carving was very easy thanks to the softness of the AAC blocks. This looked promising.

Pleased with this, I had a nice big fire and stuck the door in place after the coals had cooled off for 10 minutes. By watching the temperature I could see that this door worked well. I'll add the graph below - notice that this graph's over 28h, and the dome surface takes 6 hours to cool from 300C to 200C - twice as long as it did without the door. I thought I'd cracked it, but unfortunately:

- the sodium silicate round the edges of the door had erupted into a white fuzzy mass in the heat, and looked horrible

- the wood around the door had charred badly, causing the aluminium frame to come loose, and in one place, fall off

- the wood on the back of the door had warped with the heat and cracked, causing the thermalite block to move and crack as the wood bent. You can see one of the big cracks in the block below. The bit at the bottom is a loose chunk that fell off when I lifted the door.

The thermalite block was still solid, if a bit more brittle than before, but the wood was badly burned around the edges. This wasn't a great example of how to build a door - perhaps more of a warning to others!

Lesson 2: Don't use wood for the door - I'd underestimated just how hot it would get round the edges. This is probably my own stupid fault for putting it on when the oven was so hot...

Now I need to make door number 3 - an all metal version, probably filled with vermiculite...

Comment