This is a sticky topic.

X

X

-

Tags: None

- Stuck

-

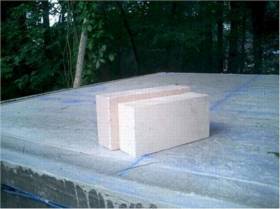

Firebrick # 1 arch

Do you see an advantage to using arched brick rather than straight. Although they cost more it seems that a more even mortar joint would be an advantage. These all appear to be medium duty or superduty firebrick where as your recomendations are for low duty. What are the disadvantages of a higher specified brick other than wood cost I have an unlimited source for free apple wood

-

Re: Firebrick Primer

Balty,

The arched brick idea is a good one... getting a nice tight mortar joint in your arch promotes strength and looks really nice. However, I'm not sure spending the extra beans on a special type of brick is the answer though... Arch sizes will vary, so the cut of the brick is dependant on the arch rise and the length of the span...

Here's my suggestion.. go down to Home Depot to the tool section where they have the miter saws, blades, etc... somewhere in there, you'll find a tool called the Angleizer.. it includes a little software program to calculate your cuts and a reusable template thats kind of like 4 adjustable rules all screwed together... it's all pretty self explanatory once you get it, but essentially all you do is plug in your span and rise and it will spit out your dimensions, which you use your template to set and mark your bricks with...

Then, I'd get a cheapo wet diamond tile saw... I recommend a 10" wet saw.. they run about $200 at Harborfreight.com (many cities have a local retail outlets).. a $60 a wet tile saw works too, they just require double the cuts since you'll have to flip your bricks each time...

Going this way, you'll be able to buy standard firebrick and cut it to suit your needs... Angleizer includes calculations for circles, half-shere's, arches, etc...

If you'd like to discuss further, PM me and we'll go from there...

JB

- Likes 1

Comment

-

Re: Firebrick Primer

Thanks JB, I'll check out the angleizer this weekend. I have a good saw (Imer 14"). I talked to MK Diamand at a trade show recently & they recomended a blade that cost over 500 bucks to cut fire brick. My sawblade is a general purpose that came with the machine. I guess I'll try this first, I was going to spring for the hard blade before I bought the brick.

Thanks for the heads up on the blade, & the invite to PM. I may take you up on it when I start cutting brick. Couple of weeks.

Rgfds

Balty

- Likes 1

Comment

-

Re: Firebrick Primer

For what it's worth, I wouldn't spend that kind of money on a blade unless I was in the trade and there was a return on investment for that kind of quality and price... The cheapo harbor freight blade that runs $30 has been working fine for me... Good luck.

JB

Comment

-

Re: Firebrick Primer

Even if you don't go to Harbor Freight, Home Depot and Lowes also have less expensive "use and toss" blades.

James

Comment

-

Re: Firebrick Primer

Bought my brick this weekend & decided to try a few cuts. I'm glad I didn't buy a special blade, he general purpose one cuts fire brick much easier & more accurate than I had expected & way easier than the sanded tudor brick I have been using to build the patio.

Thks again

Balty

Comment

-

Firebrick Question

I just located a local supplier for firebrick. He said he has both the yellow and red as "low duty." My question is: is the low duty ALWAYS the yellow color, or could he be right?

I would love to go with red if possible."You better cut the pizza in four pieces because I'm not hungry enough to eat six."

-- Yogi Berra

Forno Tito

Comment

-

Re: Firebrick Primer

JoeT,

Here, at least, the yellow firebrick are medium duty. The color really depends a lot upon where the original materials originate. Colors seem to vary, location to location. Alumina content is a more reliable guide. When you get a skid of firebrick here, about 15 per cent are brownish in color; these are a bit higher duty than the yellow, and I put them dead center in my hearth.

Jim"Made are tools, and born are hands"--William Blake, 1757-1827

Comment

-

Re: Firebrick Primer

OK, I am an idiot.

What is the best, economical way to cut firebrick used to construct to the oven? I am a masonry newbie.

Also, I would like to have a rectangular opening to the oven, rather than an arch. I was planning on using some sort of metal support. What are your recommendations?

I appreciate all the help I have gotten from this forum thus far.

Cheers & Many Thanks,

Joe

Comment

-

Re: Firebrick Primer

I use my De-Walt sliding tilting angleing wood working saw, with a 12" masonry blade from Lowes or Home Depot. I cut the bricks dry.

I have a wet brick cutter, but I wear glasses, and after cutting one brick, my glasses are splattered and I am blind. Forget wet cutting bricks!

Comment

Point taken, I will use low duty, should I persue the arched brick idea?

Point taken, I will use low duty, should I persue the arched brick idea?

Comment