Originally posted by Tractor

View Post

Announcement

Collapse

No announcement yet.

Uk custom cast oven build - Tractors oven will this work?????

Collapse

X

-

Good plan. Use a min of 2% by weight of the dry castable mix for the stainless needle addition and make sure you get the correct plastic fibres. You need polypropylene fibres, don't try cutting up some polypropylene rope. I've done some tests on them and found they do not melt at a low enough temp. You need the short super fine stuff that is one of many types used for concrete reinforcing. You can get them from concrete technology suppliers. Around half a handful for a batch of 20 L of castable is sufficient, but you need to mix about double the normal time to get good dispersal through the mix.Kindled with zeal and fired with passion.

-

Thanks for the info David much appreciated.

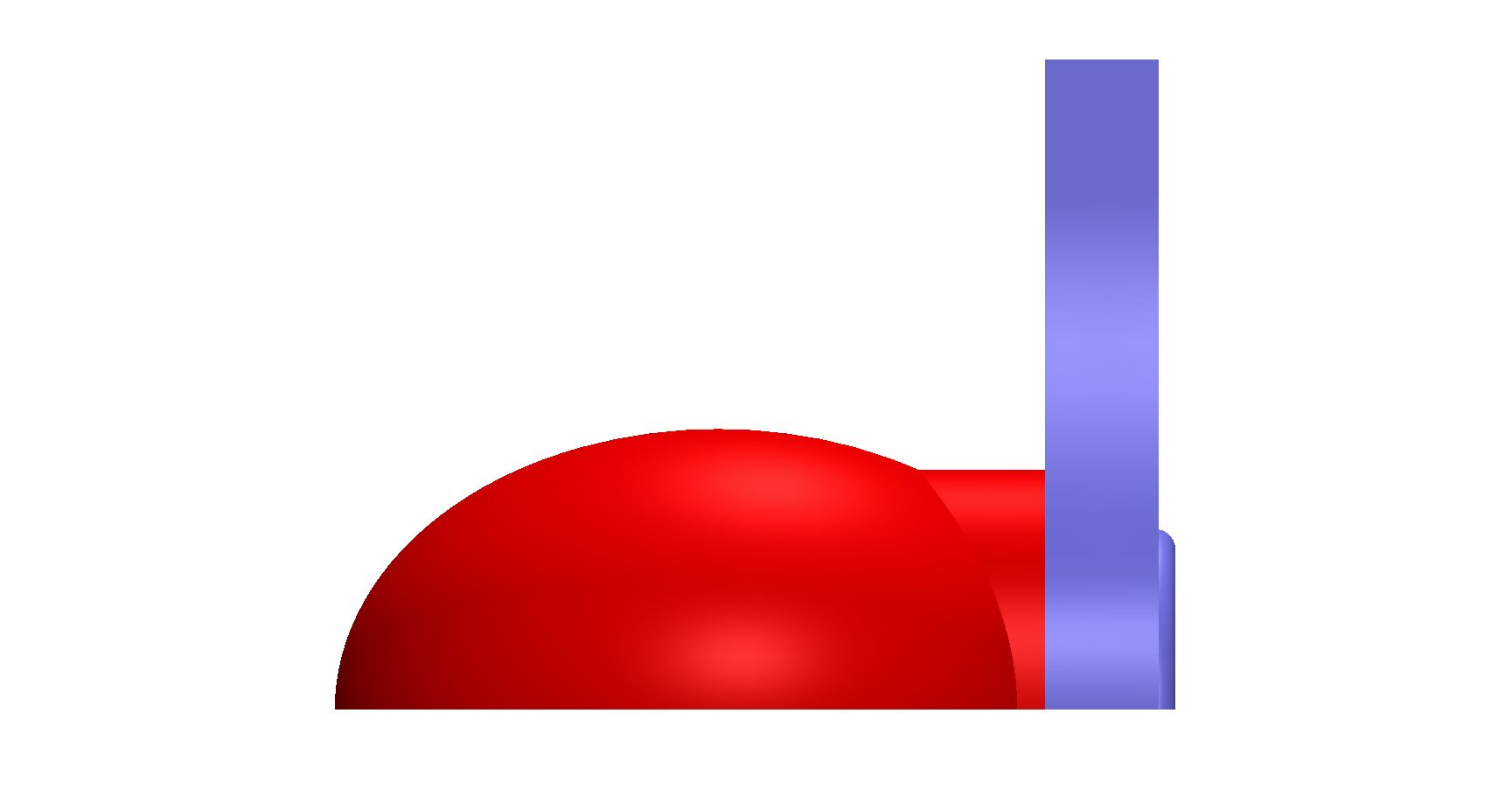

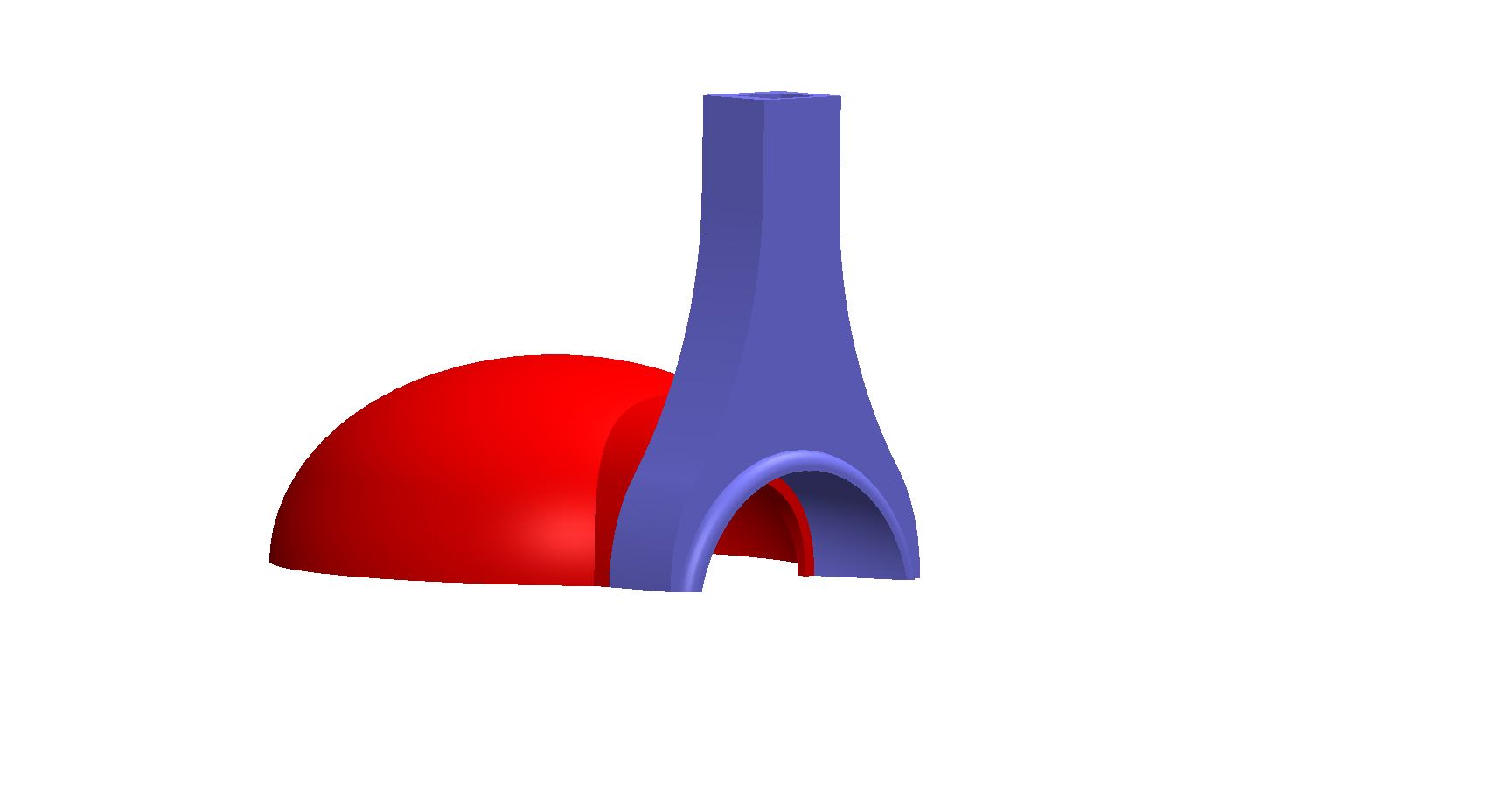

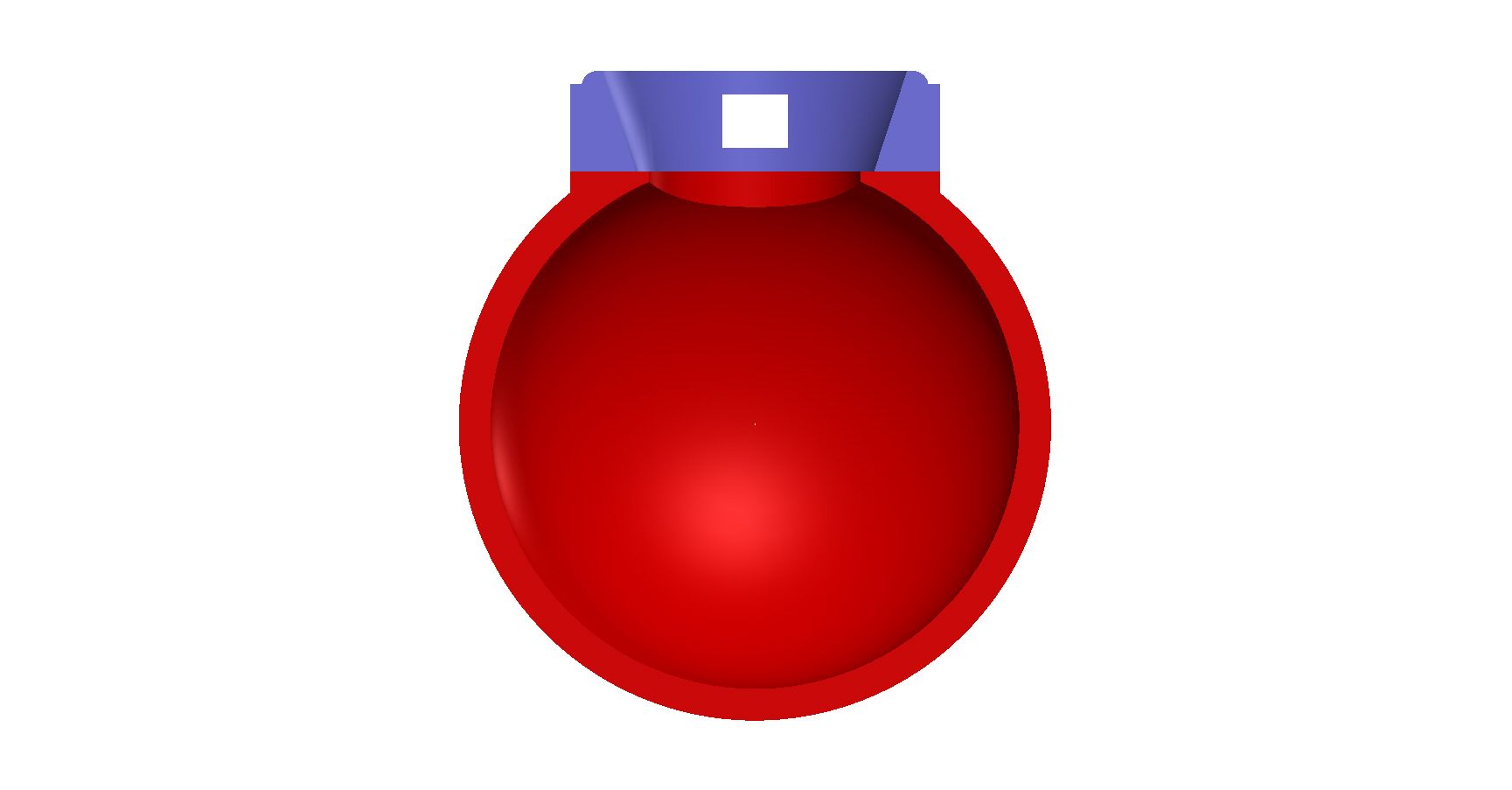

I've been playing around with a couple of new forms today and I thought I'd share this one with you. ( the more I do this the more I feel like I'm reinventing the wheel but I've got to try 😀

What I was thinking of doing was maybe casting the red sections using the 4-1-1-1 home brew mix and then maybe casting the chimney section in an insulation mix (not found a good one yet) but building on what David said earlier I might try and separate the two with a cut to shape sheet of vermiculite board and point it in with some fire cement ?

Here's the form I've been playing with today....

This is still based on 1000mm cooking floor and a 350mm high dome and this also gives me a throat depth of 160mm which with the angled entrance should give me plenty of access

Can anyone recommend any decent insulation mixes that will give me a good surface finish?

If not I guess I could cast the chimney in two sections splitting it vertically with the rear section being insulation mix and the front being traditional casting material. Roughly only a quarter of the chimney will be visible anyway

Cheers

TracLast edited by Tractor; 11-09-2015, 01:45 PM.

Comment

-

As you are willing to use the Homebrew mix as your castable for the dome you may as well use it for your insulation mix. Replace half the fine aggregate with perlite or vermiculite. Ie 2:2:1:1:1 perlite, sand, lime, Portland cement, clay.Kindled with zeal and fired with passion.

Comment

-

-

I don't see why you need to separate the two sections. Unless you were planning on building a thermal break there, in which case you can cast over a couple of layers of corrugated cardboard there, remove it after the cast has dried and fill it with ceramic blanket, vermicrete or ceramic rope. It is easier, if you are casting in place, to cast the dome first, providing some form work for the door rebate. Once cured, for a min of one week for homebrew, remove the form work around the door and the mould under the dome, then build a sandcastle at the oven mouth, cover with wet newspaper and cast you flue gallery.

Using a mix of sand with 8-10% water by volume and a little powdered clay added, makes an excellent mould.Kindled with zeal and fired with passion.

Comment

-

Remember that the flue gallery needs to be strong enough to support the flue as well as be resistant to abrasion from oven tools and feeding the fire. Use the attachment as a guide.Originally posted by david s View PostAs you are willing to use the Homebrew mix as your castable for the dome you may as well use it for your insulation mix. Replace half the fine aggregate with perlite or vermiculite. Ie 2:2:1:1:1 perlite, sand, lime, Portland cement, clay.

Attached FilesLast edited by david s; 11-10-2015, 03:28 AM.Kindled with zeal and fired with passion.

Comment

Comment