Re: dmun's 36" geodesic oven

Your point is well taken. It happens that the points on the ends of the triangles have not deteriorated at all: all the cracking was between the preassembled polygons.

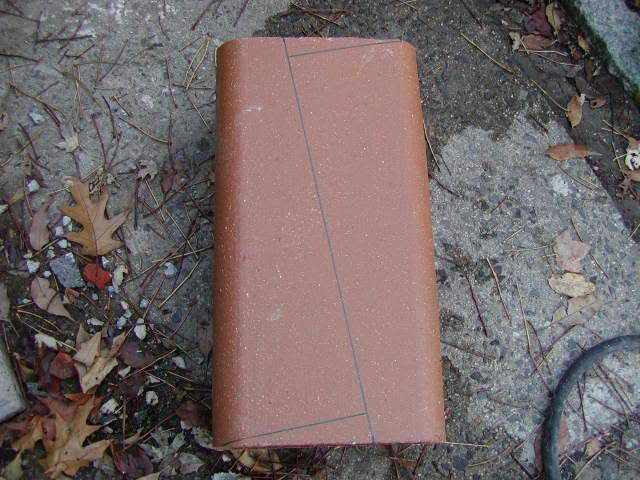

The key fault with my design was it's thinness. If you could make a geodesic oven with the standard 4 1/2 inch thickness, I'm sure it would be much more stable.

The only thing that would be of concern to me would be the fine points of the cuts.In firework we never have any cuts to small or fine to a sharp point as they can be very suseptable to thermal shock and crumbling or breaking off.

The key fault with my design was it's thinness. If you could make a geodesic oven with the standard 4 1/2 inch thickness, I'm sure it would be much more stable.

Comment