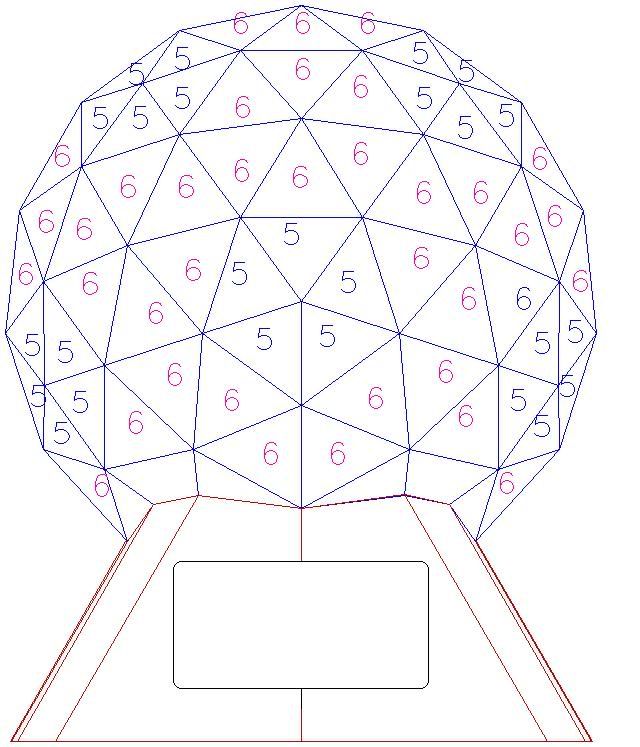

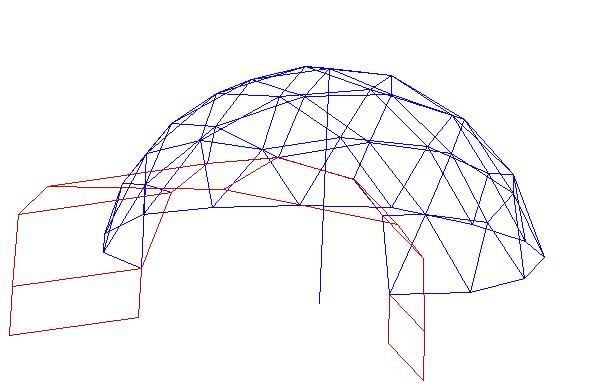

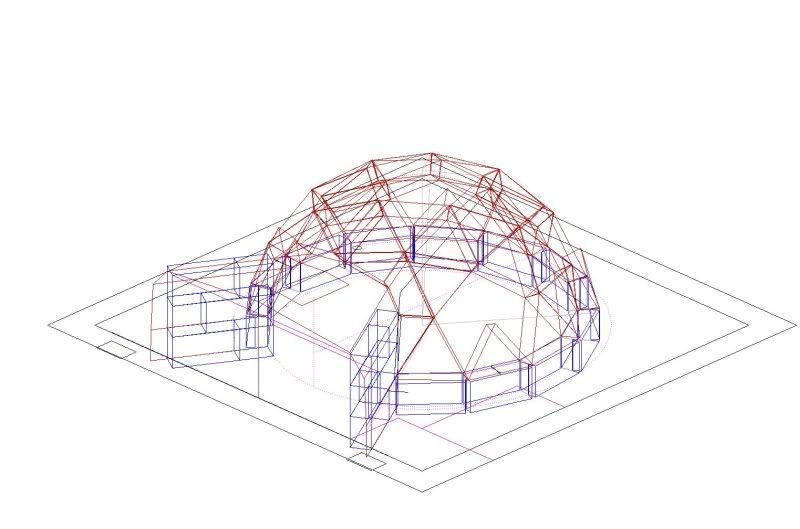

This post marks the start of the construction of my pompeii inspired oven. There has been a lot of discussion about how the bricks could be cut so that they fit evenly,without mounds of mortar. This usually involves the idea of three dimentional trapezoids, which are different on every level. My idea is to create an oven using the form of a geodesic dome. Anyone who has seen a soccer ball is familiar with the idea:

It's hexagons alternating with pentagons. Geodesic domes are constructed from triangles, and the pentagons are made of five triangles, and the hexagons from six triangles. What size to make the triangles? Here's a handy web-based dome calculator from Desert Domes.

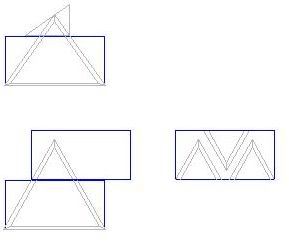

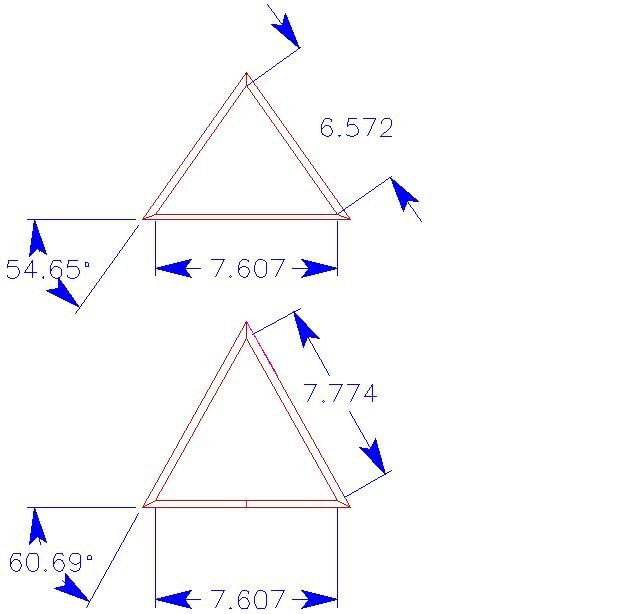

But, but, but, (I hear you say), fire bricks are rectangles and you need triangles, and triangles with 6 1/2 degree tapered edges! This is crazy!

That's it exactly. I am crazy, and I'm not advocating that anyone else do this. If you want a perfect fit oven, buy one of James' modular ovens. As I explained to a friend the other night: You've heard of labor-saving appliances? Well a wood-fired brick oven is a labor-consuming appliance.

It's hexagons alternating with pentagons. Geodesic domes are constructed from triangles, and the pentagons are made of five triangles, and the hexagons from six triangles. What size to make the triangles? Here's a handy web-based dome calculator from Desert Domes.

But, but, but, (I hear you say), fire bricks are rectangles and you need triangles, and triangles with 6 1/2 degree tapered edges! This is crazy!

That's it exactly. I am crazy, and I'm not advocating that anyone else do this. If you want a perfect fit oven, buy one of James' modular ovens. As I explained to a friend the other night: You've heard of labor-saving appliances? Well a wood-fired brick oven is a labor-consuming appliance.

Am I missing something?

Am I missing something?

Comment