Yeah, that variance looks like a problem

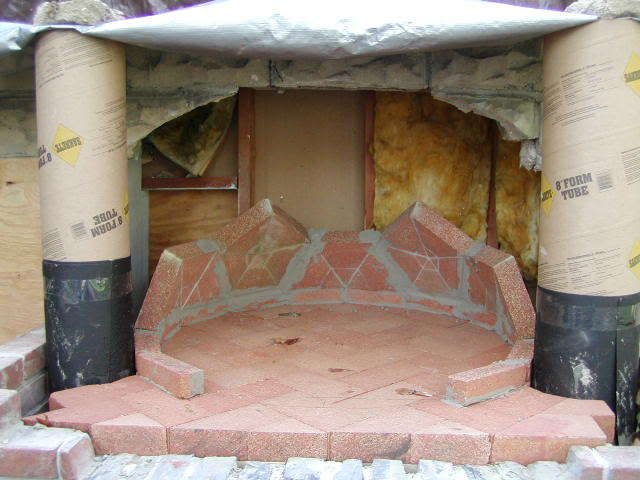

The size of those pieces looks like they will need good support until cured. You don't have the advantage of building self supporting courses, but it will have tight seams. I'm guessing you have a support structure in the works. I like it.

The size of those pieces looks like they will need good support until cured. You don't have the advantage of building self supporting courses, but it will have tight seams. I'm guessing you have a support structure in the works. I like it.

Comment