Re: My indispensible tool (a variation on a FB theme)

Looks great. Love how the joints in your dome look. I am sure they look spectacular from the inside too. I build these for a living and prefer the sand mold method. It requires a bit of shoveling (of sand) but its fool proof and allows multiple layers to be built at the one time. Use styrofoam boxs as infilling with the sand over the top. Great gadget tho!

Announcement

Collapse

No announcement yet.

My indispensible tool (a variation on a FB theme)

Collapse

X

-

Re: My indispensible tool (a variation on a FB theme)

Jim

I finished with the tool and as promised, passed it with all your accesories to a another WFO Builder here in SD. (Eric Prante - eprante). Also passed him my plywood floor template and both arch supports so he got the complete do it yourself kit. Your tool worked great through out and made for a perfect dome. Thanks again.

Leave a comment:

-

Re: My indispensible tool (a variation on a FB theme)

The jig I built is essentially just a turnbuckle and 3/8'"-18 threaded rod. I welded a bolt onto one yoke end and it goes into a T-nut, which is in turn recessed into the center of the plywood. It is infinitely adjustable from 18-24", allowing me to build from 36-48" ovens in the future.

The fine range of adjustability (each turn is 1/18") also allows for making a lower, flatter, elliptical dome (as long as the floor diameter is greater than 36") and eliminates the increase in dome height due to starting above the actual floor brick.

I had toyed with this idea a couple of years ago, but was only going to use it to locate the bricks before mortaring them. The cradle and clamp idea to actually hold the bricks in place seems so simple that I don't know why I didn't think of it at that time.

This could be made with no welds if the floor end used an end yoke and a clevis-type eyebolt. This was about $15 in materials.2 Photos

Leave a comment:

-

Re: My indispensible tool (a variation on a FB theme)

Keep in mind when building the tool that the higher off the floor the pivot point is (hinge, ball joint, lazy susan, whatever) the higher your ceiling is going to be. So on a 42" oven if the pivot is 2.25" from the floor (As I have seen in some instances), the distance between wall at soldier course and center of floor will be 21" but the distance between center-top of ceiling and floor will be 23.25".

Also for best results make certain all components are square to one another and that the pivot aligns with center of brick (see earlier post).

JimLast edited by jcg31; 06-29-2009, 07:54 PM.

Leave a comment:

-

Re: My indispensible tool (a variation on a FB theme)

What's the word? Oh ya, genius.

Thanks a lot.

Mark

Leave a comment:

-

Re: My indispensible tool (a variation on a FB theme)

I placed a PVC end cap on the tip of the tool that is what covered the head of the bolt. I had to bevel the end so that I was able to lift the tool out of the way. The long nut is a threaded coupling backed up with a wing nut. This is not a great picture but I hope it helps.1 Photo

Leave a comment:

-

Re: My indispensible tool (a variation on a FB theme)

RES10CUE

I'm trying to figure out how you did the no weld on the angle where it attaches to the long nut so it is flush or is it flush? Is the brick just resting on the head of a bolt? I need to laid down the floor and then I start building the dome and have most of the pieces to build the jig but I'm stuck on that issue.

MarkLast edited by DOC Opa; 06-16-2009, 02:52 PM.

Leave a comment:

-

Re: My indispensible tool (a variation on a FB theme)

Jim

Tool is working great.

Lot's of pictures of of your genius being put in to action on my thread.

thanks again.

Greg

Leave a comment:

-

Re: My indispensible tool (a variation on a FB theme)

Hey Kelbor,

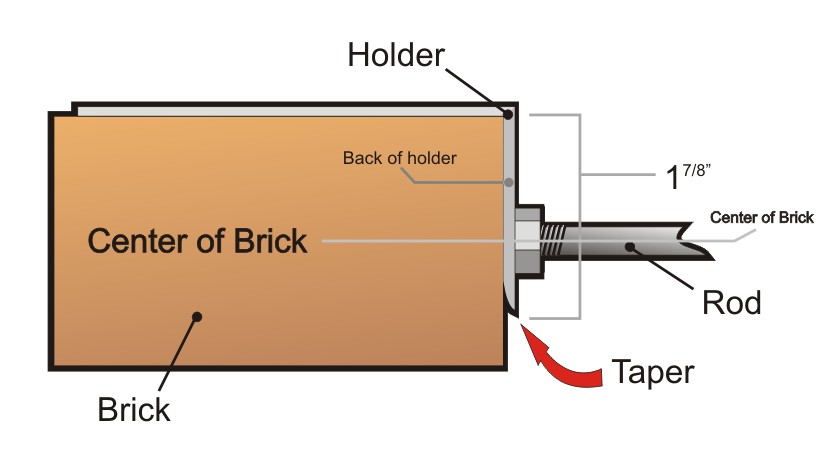

As long as your rod is attached to the back portion of the holder (bpoh) at the center of the brick, and the bpoh is 1 7/8" from the base of a 2.5" thick brick, and you taper the top of the bpoh as illustrated below, it will be snug but it won't disturb the brick once in place when you remove the tool. You shouldn't have to make any adjustments to the tool to do this, that would greatly affect the consistency of results and speed inherent in its use.

Jim

Originally posted by Kelbor View PostSo, I built one of these tools in the "no weld" fashion, have not used it yet, and then while showing a friend last night he asked an interesting question. My tool uses a right angle bracket for the brick support/guide. Does this guide need to be removed or loosened when moving from one brick to the next? the reason I ask is because it appears that the end of the bracket that points down will catch on the brick as I am trying to reposition the support arm for the next brick. Is this making sense? Maybe the answer will be obvious once stacking has begun.Last edited by jcg31; 05-08-2009, 05:02 AM.

Leave a comment:

-

Re: My indispensible tool (a variation on a FB theme)

- Harbor Freight Tools - Quality Tools at the Lowest Prices

Got this on sale today. It has a hole in the bar and I will use a caster wheel from HD. I will take the wheel off and put a screw throught the hole at the end of the bar. Then screw the base of the caster to my plywood. I will post pic when finished. Hope this works....

Leave a comment:

-

Re: My indispensible tool (a variation on a FB theme)

So, I built one of these tools in the "no weld" fashion, have not used it yet, and then while showing a friend last night he asked an interesting question. My tool uses a right angle bracket for the brick support/guide. Does this guide need to be removed or loosened when moving from one brick to the next? the reason I ask is because it appears that the end of the bracket that points down will catch on the brick as I am trying to reposition the support arm for the next brick. Is this making sense? Maybe the answer will be obvious once stacking has begun.

Leave a comment:

-

Re: My indispensible tool (a variation on a FB theme)

I have also adapted the process of the "Indespensible Tool" I placed a lazy susan turntable on 3/4" plywood with a hinge with all thread with a simpson tie placed on the end. So far I have used it to help with my cuts. I have not started setting my peices yet but I can tell, it is the "Indespensible Tool". Thanks for all the help.4 Photos

Leave a comment:

-

Re: My indispensible tool (a variation on a FB theme)

I am starting to work on my dome now. Sure would be interested in getting one of these tools anyone???

Leave a comment:

-

Re: My indispensible tool (a variation on a FB theme)

Looks great Doug - Love the no weld approach! And clean too (that won't last long). Good luck with the build.

Jim

Leave a comment:

-

Re: My indispensible tool (a variation on a FB theme)

Here's another variation: I'm not a welder so this is all stock hardware, with the exception of the aluminum angle at the end which I drilled and tapped to attach to the threaded rod. The clevis rod end ("yoke") attaches to an eyebolt which is threaded into a nut recessed into the underside of the plywood template. So far, I like the adjustability of it with the threaded rod. The plywood template is in three pieces so I'll be able to slide it out of the oven opening when I'm done. The clevis rod end was about $9.00 from McMaster Carr, the rest is stuff I had laying around, probably could build this for under $20. I am just getting to the point of actually using this tool (I have to admit, as soon as I saw the original post on this tool I just had to have one! Thanks Jim) but I'm pretty sure it will live up to it's "indispensible" reputation.

Doug1 Photo

Leave a comment:

Leave a comment: